Why Cylindrical Fuses Are the Core of Modern Electrical Protection Systems?

In today’s fast-paced industrial and residential power networks, Cylindrical Fuses have become a cornerstone of electrical protection. These compact yet powerful devices play an essential role in safeguarding circuits from overcurrents, short circuits, and equipment failure. With the rise of automation, renewable energy integration, and high-efficiency electrical systems, the demand for reliable and space-efficient protection devices has grown significantly.

What Is a Cylindrical Fuse and How Does It Work?

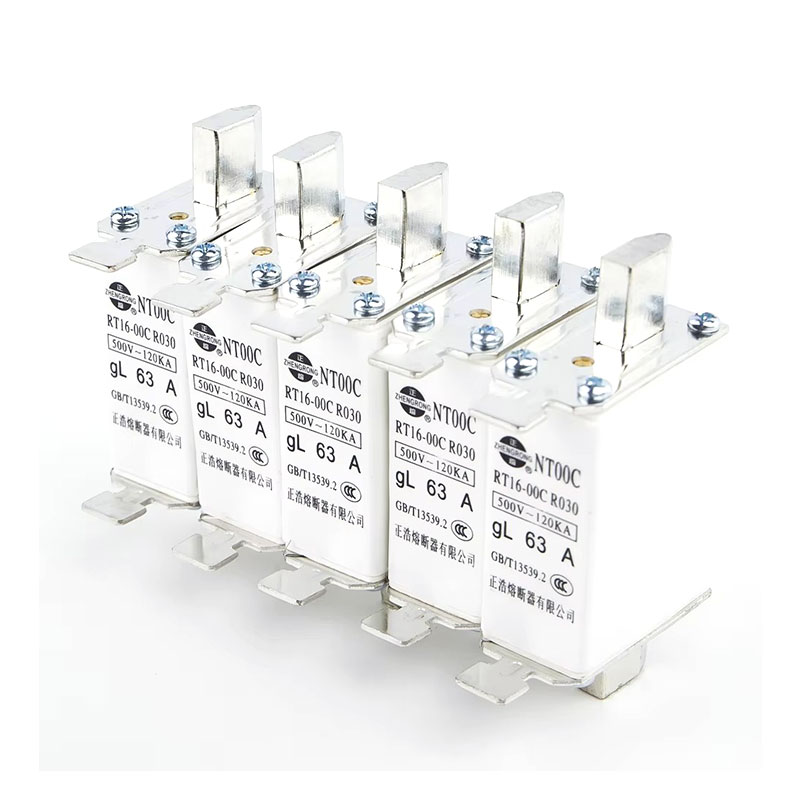

A Cylindrical Fuse is a type of low-voltage protective device that interrupts electrical flow when a circuit exceeds its rated current capacity. Designed with a cylindrical ceramic or glass body, metal end caps, and a fuse element inside, it provides both reliability and simplicity in overcurrent protection. When excessive current passes through, the fuse element melts, breaking the circuit instantly to prevent equipment damage or fire hazards.

Unlike conventional fuses, cylindrical types offer uniform contact, easy installation, and precise rated current control. They are commonly used in industrial control panels, power distribution systems, electrical cabinets, EV charging stations, and home energy management systems.

Technical Parameters of Cylindrical Fuses

| Parameter | Description |

|---|---|

| Rated Current | 0.5A – 125A |

| Rated Voltage | 250V AC / 500V AC / 690V AC (varies by model) |

| Breaking Capacity | Up to 120 kA |

| Fuse Size Standards | 10×38mm, 14×51mm, 22×58mm |

| Fuse Element Material | Silver or Copper |

| Fuse Body | High-strength ceramic or glass |

| Mounting Type | Panel mount, inline, or fuse holder mount |

| Operating Temperature | -40°C to +125°C |

| Compliance | IEC 60269 / UL248 standards |

Why Are Cylindrical Fuses Essential in Electrical Protection Systems?

The increasing complexity of modern electrical systems demands superior safety mechanisms. Cylindrical fuses provide several distinct advantages that make them indispensable in industrial, commercial, and residential applications.

a. High Breaking Capacity

Cylindrical fuses can safely interrupt high fault currents without generating excessive heat or arcing, ensuring the safety of connected equipment and personnel.

b. Compact and Modular Design

Their small form factor allows integration into confined spaces such as control panels and switchboards, while still providing high-level protection.

c. Consistent Performance

With precise current-limiting characteristics, cylindrical fuses react swiftly and predictably to overcurrents, providing consistent circuit protection and preventing cascading failures.

d. Easy Replacement and Maintenance

Unlike molded circuit breakers, cylindrical fuses are easy to replace, making them ideal for systems that require minimal downtime or are located in remote or high-demand environments.

e. Cost-Effective Safety Solution

They provide a cost-efficient protective measure compared to electronic circuit protection systems, offering both performance and long-term reliability.

f. Environmentally Friendly Construction

Cylindrical fuses are often made from recyclable materials such as glass and ceramics, aligning with global sustainability goals and environmental standards.

How Are Cylindrical Fuses Evolving with Technology and Industry Trends?

The electrical industry is undergoing rapid transformation with trends such as smart grids, renewable energy, and electric mobility. Cylindrical fuses are adapting to these changes by integrating enhanced performance capabilities and smarter safety features.

a. Renewable Energy Integration

As solar and wind power systems expand, there is a growing need for fuses that can handle DC currents efficiently. Cylindrical fuses are being designed with higher voltage ratings (up to 1000V DC) to protect photovoltaic systems and battery storage solutions.

b. Electric Vehicle (EV) Charging Infrastructure

Modern EV chargers rely on compact protective devices to ensure safety during fast charging. Cylindrical fuses with fast-acting characteristics are increasingly used in AC/DC converter circuits, inverters, and control modules.

c. Smart Grid and IoT Integration

Next-generation cylindrical fuses are being developed with sensor-enabled holders that can communicate fuse status to monitoring systems. This trend allows predictive maintenance, reducing the risk of system downtime.

d. Industrial Automation

In highly automated manufacturing environments, electrical reliability is critical. Cylindrical fuses provide robust protection against sudden surges, helping to maintain operational efficiency and minimize losses.

e. Miniaturization and Efficiency

As industries move toward smaller, more efficient designs, manufacturers are innovating ultra-compact fuses that maintain the same high breaking capacity while saving space and weight.

These advancements signify that cylindrical fuses are not only traditional protective devices but also vital components of the future smart power ecosystem.

Frequently Asked Questions (FAQs) About Cylindrical Fuses

Q1: What is the difference between a cylindrical fuse and a blade fuse?

A: A cylindrical fuse is typically used in industrial and commercial systems due to its higher voltage and current ratings. It features a round body with end caps for screw or clip mounting. A blade fuse, on the other hand, is mainly used in automotive applications, featuring flat, push-in metal terminals designed for low-voltage circuits. Cylindrical fuses offer higher breaking capacities and are better suited for heavy-duty applications.

Q2: How do I choose the correct cylindrical fuse for my system?

A: Selecting the right fuse requires evaluating several key factors:

-

Rated Voltage and Current – Match or slightly exceed your system’s operating parameters.

-

Breaking Capacity – Ensure the fuse can safely interrupt the maximum possible fault current.

-

Time-Current Characteristics – Choose between fast-acting or time-delay types depending on the load sensitivity.

-

Environmental Conditions – Consider temperature, humidity, and vibration.

-

Fuse Size Standard – Confirm compatibility with the fuse holder or circuit design.

For complex systems, consulting the manufacturer’s technical datasheet is essential for accurate selection.

The Future Outlook and Market Potential of Cylindrical Fuses

The global demand for cylindrical fuses is expected to grow steadily as industries shift toward electrification, renewable power, and digital control. With increasing regulations around electrical safety and energy efficiency, cylindrical fuses will continue to evolve as key components in power management solutions.

In the next decade, the market is forecasted to witness a significant rise in adoption driven by:

-

Expansion of EV charging networks.

-

Growth of industrial automation.

-

Increased focus on power reliability in data centers.

-

Rising implementation of distributed energy systems.

Manufacturers are responding by introducing fuses with advanced materials, higher DC voltage ratings, and smart monitoring features. The convergence of traditional safety design and digital intelligence positions cylindrical fuses as pivotal devices in next-generation electrical infrastructure.

Cylindrical fuses stand as one of the most reliable and efficient solutions for electrical circuit protection. Their proven technology, adaptability, and cost-effectiveness make them indispensable across multiple industries — from renewable energy and EV infrastructure to industrial automation and residential power distribution. As the global focus on safety and sustainability intensifies, cylindrical fuses will continue to evolve, integrating intelligent features and supporting high-efficiency power systems.

Zhenghao Fuse, a trusted manufacturer with extensive expertise in fuse technology, provides a complete range of cylindrical fuses designed to meet international standards and customized needs. For detailed specifications, technical support, or product inquiries, contact us to discover how Zhenghao Fuse can enhance your electrical safety and system reliability.

- Why Your Solar Array's Safety Hinges on Choosing the Right Photovoltaic DC Fuse

- What Makes Float Switches the Key to Smarter and Safer Liquid Level Control in Modern Industries?

- How Does a Cylindrical Fuse Protect Electrical Systems?

- Why Choose a Screw Type Fuse Over Other Fuse Types

- Constantly having circuit protection issues?

- What is Solar Connector?